Aluminum Battery Box Match-Up Guide: In-Frame vs Side-Pack vs Stack-Pack

An aluminum battery box does more than protect your Group 31s from road grime—choosing the right form-factor can reclaim frame space, simplify service, and even boost payload by shedding dozens …

An aluminum battery box does more than protect your Group 31s from road grime—choosing the right form-factor can reclaim frame space, simplify service, and even boost payload by shedding dozens of pounds versus steel. Merritt builds three heavy-duty families to cover almost every chassis layout: In-Frame, Side-Pack, and Stack-Pack. Use the chart and deep-dive below to pick the best fit for your tractor, tanker, or vocational rig.

| Battery-box family | Mounting footprint | Battery capacity | Why choose it? |

|---|---|---|---|

| In-Frame Battery Box | Drops between frame rails; ships with mounting kit—no frame drilling required | 2 or 4 Group 31 | Saves side clearance for tanks or fairings; lowest center-of-gravity placement. |

| Side-Pack Battery Box | Bolts to side frame; optional knurled step version | 2, 4 or 6 Group 31 | Easy ground-level access; step models double as cab entry on day cabs. |

| Stack-Pack Battery Box | Vertical or horizontal “stack” for tight wheel-base or bulkhead installs | 4 or 6 Group 31 (add-on trays) | Packages high amp-hours in the smallest footprint—perfect for PTO, mixer, or pump chassis. |

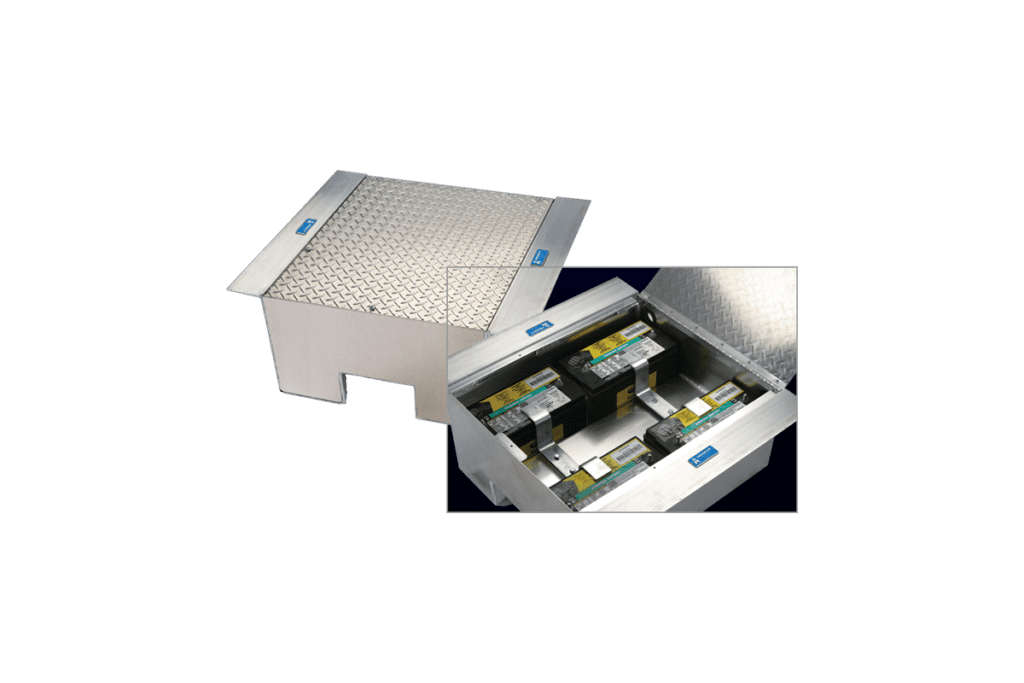

In-Frame Battery Box – Lowest Profile, Quickest Install

- Who it’s for: Sleeper tractors, tankers, and any spec where side real estate is at a premium.

- Key advantages

- No-drill hardware included—drop the box, torque the U-bolts, done.

- Natural aluminum corrosion resistance keeps road salt from eating the tray.

- Holds two or four batteries; hinged lid protects tops from spray.

- Watch-outs: Verify clearance above cross-members and driveline; check DEF tank routing before final bolt-up.

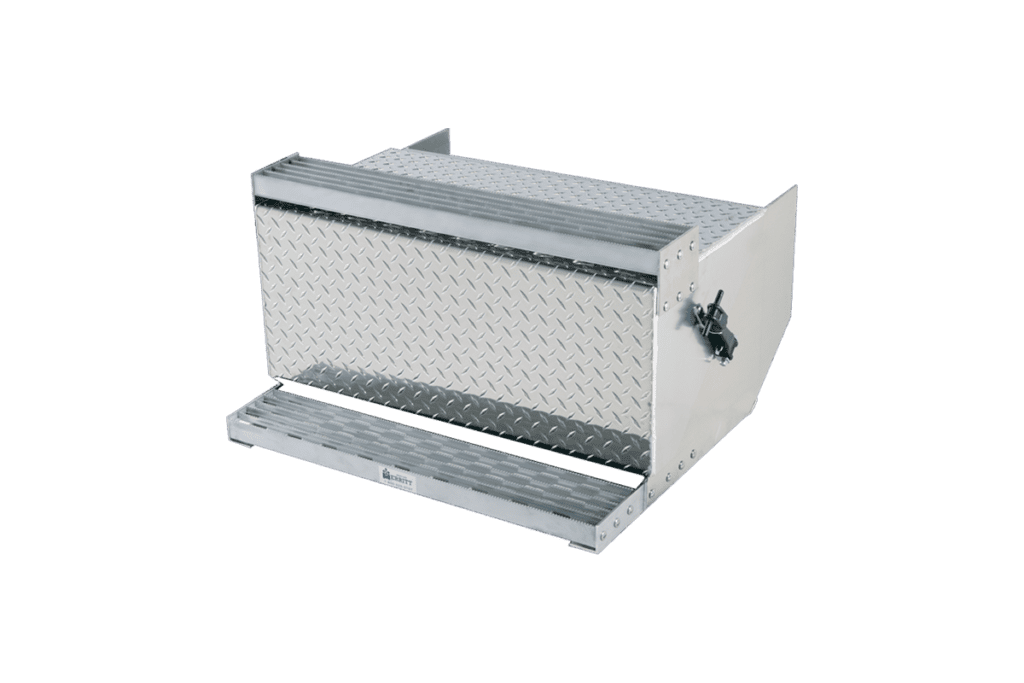

Side-Pack Battery Box – Easy Access + Optional Step

- Who it’s for: Day cabs, vocational tractors, and fleets needing walk-up battery service.

- Key advantages

- Choose step or no-step models—knurled tread lets drivers enter the cab safely.

- 2-, 4-, or 6-battery versions cover everything from line-haul tractors to heavy haul.

- Works with Merritt frame-drill or no-drill L-brackets for fast swaps.

- Watch-outs: Door swing must clear tanks/fairings; measure fairing depth before ordering deeper 6-battery units.

Stack-Pack Battery Box – Maximum Capacity, Minimal Footprint

- Who it’s for: Concrete mixers, dump trucks, pumpers—any chassis with limited length but room to build vertically.

- Key advantages

- Vertical or horizontal stack orientation; add trays for up to six Group 31s in one enclosure.

- Diamond-plate exterior shrugs off aggregate and debris in off-road sites.

- Same laser-cut, lap-welded aluminum body as other Merritt boxes—lighter than steel, tougher than stamped imports.

- Watch-outs: Account for lift-off clearance if you mount vertical; wire harness length may need extension on shorter wheelbases.

Quick Install Tips

- Use the hold-down kit—every Merritt box ships with or offers an optional clamp set that keeps batteries from bouncing (required for DOT compliance).

- Torque stainless hardware with anti-seize to avoid galling during annual checks.

- Route vent tubes away from hot exhaust components; aluminum transfers heat quickly but batteries still prefer cooler air.

Ready to Spec Your Aluminum Battery Box?

- Browse all models: Merritt Heavy-Duty Battery Boxes

- Get a quote: Call 800-525-0107 or email alum.prod@merrittproducts.com—most SKUs ship from one of three U.S. warehouses in a week or less.

- Need a one-off size? Custom aluminum boxes leave our Colorado plant in about 10 days.

Equip your truck with an aluminum battery box that saves weight, fights corrosion, and fits your frame the first time—so you can spend more time on the road, not in the shop.