The Risks of Transfer Tank Failure

A transfer tank failure can pose several risks, depending on the cause of failure and the type of liquid being transported. Here are some key risks to consider: 1. Structural Failure Leaking tanks are very …

A transfer tank failure can pose several risks, depending on the cause of failure and the type of liquid being transported. Here are some key risks to consider:

1. Structural Failure

Leaking tanks are very common and a huge issue for dealers. Cracks and pinhole leaks being present when first delivered to a customer are a leading reason for returns and warranty replacement.

- Cracks, leaks, or ruptures due to material fatigue, poor welds, or impact damage.

- Weak seams or joints failing under pressure, vibration, or temperature fluctuations.

2. Environmental Hazards

Depending on the jobsite a leaking transfer tank can also cost hundreds of thousands of dollars for soil remediation and ground fill.

- Fuel or chemical spills leading to ground contamination and water pollution.

- Fire or explosion risks if flammable liquids leak and come into contact with an ignition source.

3. Safety Risks

- Hazardous vapor exposure causing respiratory issues or other health concerns.

- Increased accident risks if a tank shifts, detaches, or leaks while in transit.

- Potential for combustion if static electricity builds up while transferring fuel.

4. Regulatory and Legal Consequences

- Fines and penalties for failing to meet DOT, EPA, or OSHA regulations.

- Liability issues if a failure causes property damage, injury, or environmental harm.

5. Operational Disruptions

Every time a tank is out of commission, less machinery is fully functional. These downtimes can significantly impact customer relations because the longer a customer’s truck is down, the longer their job takes and the more time and money are lost.

- Downtime and lost productivity due to tank failure requiring repairs or replacement.

- Costly cleanup efforts if hazardous materials are spilled.

How to Mitigate These Risks

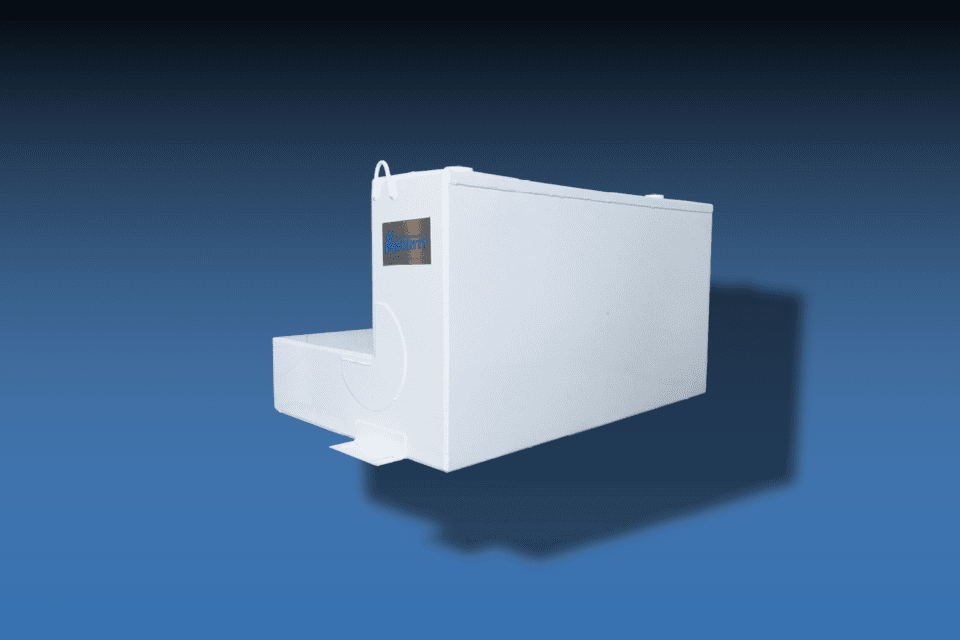

Merritt transfer tanks were built around avoiding these problems from the start. Overlapping seams, thicker body material, filler and pump port reinforcement as well as internal brackets and baffles keep trucks on the jobsite without the worry of failures and down time.

To reduce the risk of failure for any transfer tank:

- Inspect for cracks, leaks, and corrosion regularly.

- Ensure proper installation and secure mounting in vehicles.

- Use grounding cables and anti-static precautions when transferring flammable liquids.

- Follow manufacturer guidelines for usage, maintenance, and weight limits.